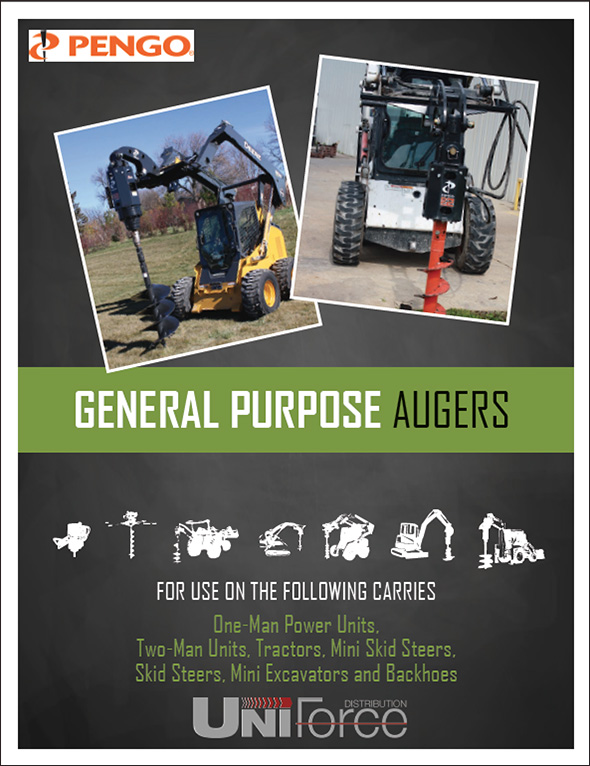

Augers

Drive Motors / Earth Drills

Applications include:

Fencing Landscaping

Tree planting

Well boring

Foundation piles

Screw pile installations

Ground source

Heat pumps

Pole and mast installations

Road signage Sound barriers

Exploration and research

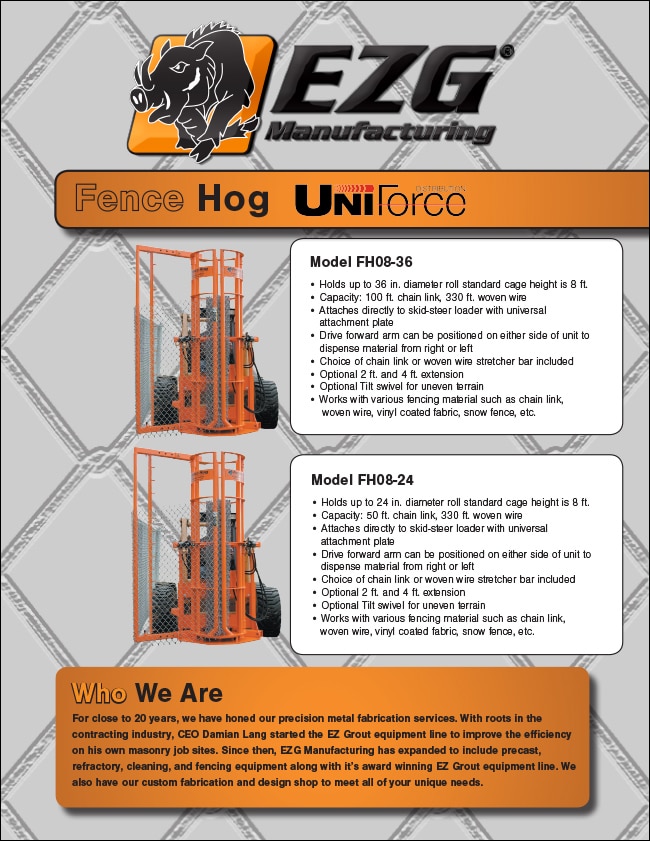

Features of our Earth Drill

Forged hood ears

Hose & Coupler options

High quality hydraulic motors

Epicyclic gearbox

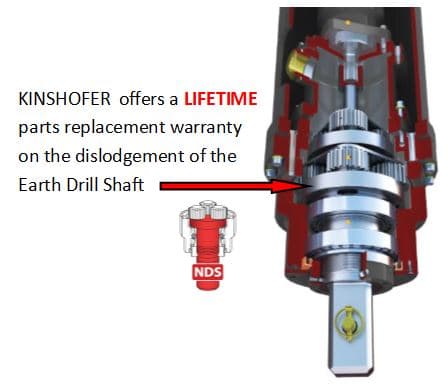

Non-dislodgement shaft

Uniforce, the benchmark for professionals!

Best Guarantee in the Industry

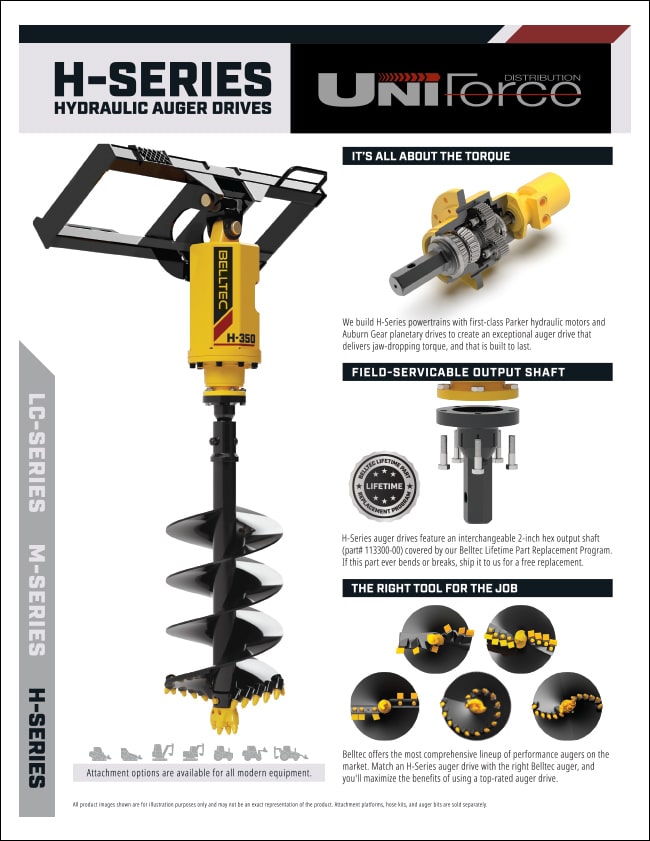

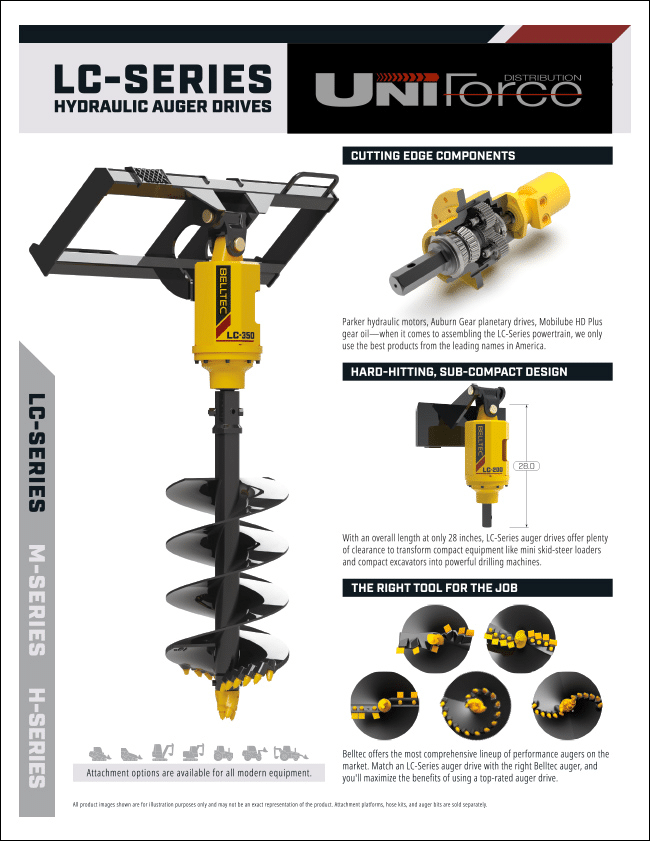

Hydraulic Drives for Drilling & Anchoring

Available for machines from 0.8 to 45 Tons

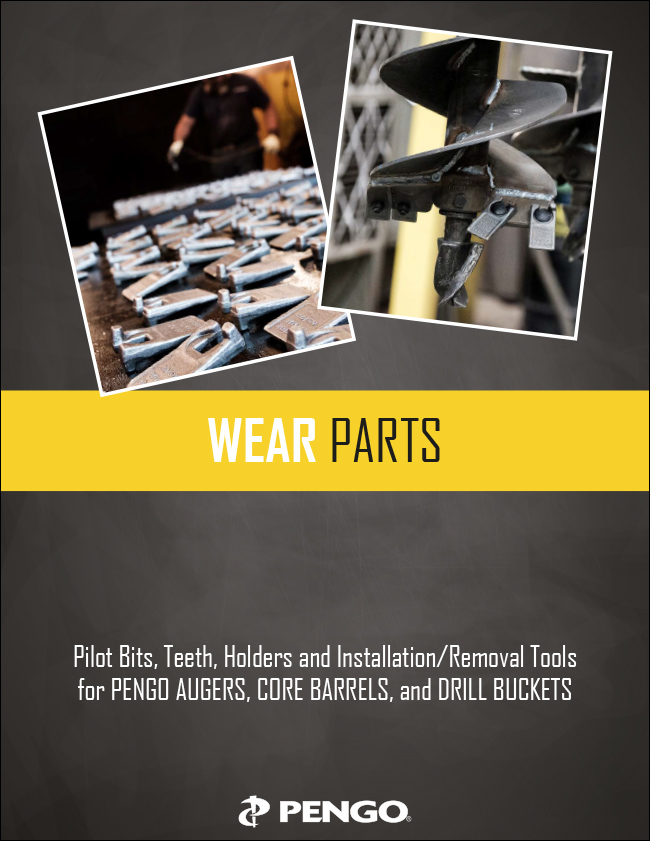

Available with Shock Lock, Tungsten or Carbide teeth.

Specialized made to order Auger bits available.

Inventory of augers from 4’’ to 48’’ for all types.

Distributor for all major brands such as:

HOSE & COUPLER OPTIONS

All Earth Drills come standard with high quality hoses and couplers (excludes larger units).

HIGH QUALITY HYDRAULIC MOTORS

We work closely with high quality suppliers to develop the most reliable attachments available on the market today.

EPICYCLIC GEARBOX

Torque is amplified by using the unique planetary gearbox. This system allows the motors output torque to be multiplied with extreme efficiency as well as ensuring the durability and reliability you need.

FORGED HOOD EARS

Standard with all Earth Drills in areas that we know will take a lot of strain. All hood pins are locked for extra safety making it impossible for the hood to detach from your hitch.

NON-DISLODGEMENT SHAFT

The Non-Dislodgement Shaft is a single piece drive shaft assembled top down and locked into the Earth Drill housing. This design guarantees that the shaft will never fall out, making for a safer work environment, not only for the operator but also any surrounding workers, a MUST-HAVE FEATURE for any safety conscious company.

HUB OPTIONS Augers are available with all major standard hubs on the market, including: 2”, 2.5”, 3”and 4” Hex 2” and 2.56” Round 2.25”, 2.96”, 3.94”, 4.33” and 5.125” Square …to name but a few.

4″ to 42″ bits available

In addition to the tine configuration, the angle of the tine holders has also been optimized. Soil is directed into the spiral path more efficiently for a fresh cut with every revolution, preventing clogging.

Using a telescopic extension improves efficiency when drilling deep holes. The telescopic extension is placed inside the bit, so storage space is reduced to a minimum. In addition to standard extensions with fixed length, UniForce offers you a range of telescopic extensions for S5, S6 and PA series augers.

Shock Lock auger tooth holders can be supplied with Earth and Tungsten teeth. Interchangeable drivers allow for different ground conditions. Rock tines have cone locking. Additional drivers, Earth, Tungsten, Cave and Rock are available.

Robust forged construction and easy assembly. Pilot extensions allow the auger to maintain its axis precisely in difficult soil. Improves performance on sloping terrain. Industrial anchor screw technology. Keeps soil on the turns during removal. The most efficient ratio between the amount of soil removed and the speed of operation.

Our unique, patented Shock Lock TM tooth locking system is designed to reduce breakage due to wear, using a shock-absorbing rubber strip. A locking pin prevents tooth loss.

HEAVY DUTY TUBE We know that our Augers can expect a tough life, so we only use the highest-grade steel and vary our tube size according to machine size and application. Our Augers have a reputation of being the toughest on the market.

SHALLOW PITCH FLIGHTS

By working with and, more importantly, listening to operators feedback we have developed the perfect pitch for our flights. It will cut at its maximum efficiency and, most importantly the spoil will stay on your Auger when you remove it from the hole.

CONSTANT SPIRAL CUT

Our boring heads are designed with a Constant Spiral Cut. Teeth are located so that each makes its own fresh cut on every revolution and are angled to direct spoil towards the centre of the auger. The tooth cutting angle ensures spoil is broken up thoroughly to avoid any clogging.

PILOT AND TOOTH OPTIONS Augers are offered with many different tooth and pilot options to suit your specific need. For example, in the S4 range we offer up to eight different combinations and we have the know-how to help you select the optimal configuration.